Environmental decontamination is essential for health and safety.

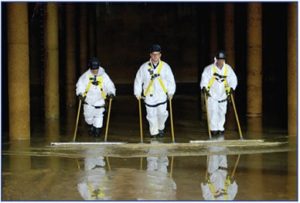

Environmental decontamination is also known as environmental disinfection or environmental cleaning. It is the process of thoroughly cleaning and disinfecting surfaces in a healthcare environment to rid them of a harmful level of contamination. Companies like Jet Blast Inc. can be trusted to handle this vital healthcare process for you, using the proper environmental decontamination cleaning tools and best practices. Learn more about this topic below.

What Is Environmental Decontamination?

Environmental decontamination is the cleaning of healthcare facilities to eliminate sickness from the healthcare environment. It brings contaminants in the area down to a low enough level that they do not provoke healthcare-associated infections (HCAIs.) These contaminants include microbes (germs and viruses) and non-microbial substances (bodily fluids, dust, etc.)

The categories for different surfaces needing environmental decontamination include non-critical, semi-critical, and critical surfaces.

- Non-critical surfaces are those that would only affect the patient by touch, such as door knobs and bed railings.

- Semi-critical surfaces may have contact with mucous membranes.

- Critical surfaces are internal to the patient; these would include surgical tools.

Environmental disinfection includes both cleaning and disinfecting. Cleaning removes apparent dirt from surfaces like machines and tools, but disinfecting removes as many pathogens as possible. It is impossible to remove every single microbe in an environment, but it is possible to keep the microbe population low enough to prevent HCAIs.

Best Practices in Environmental Decontamination

Environmental decontamination cleaning follows several fundamental best practices for the best results. They are as follows:

- Use hospital-grade cleaners. A neutral detergent is recommended for removing contaminants without leaving a chemical film behind.

- Clean from cleanest to dirtiest. Tackling the cleanest surfaces first limits the spread of contaminants onto already cleaner areas.

- Do not use cleaners or cleaning tools that spread chemicals, dust, or dirt through the air.

- Follow the manufacturers’ directions on how to prepare cleaning chemicals for use, such as dilution according to a specific percentage.

- Conduct bacteriological monitoring for extra assurance of the quality of the healthcare environment.

Contact Jet Blast Inc. Today!

Jet Blast® Industrial Services strives every day in an effort to provide our customers with the best service and equipment possible. Providing a safe and stable workplace has allowed us to keep a team of quality people with most having a tenure of 15 – 25 years with Jet Blast®. With all that experience under one roof, we have been able to provide reliable 24-hour service since 1979. I believe this helps to set us apart from the competition.

Compare us! Let us make your job easier. If you’re located in Maryland, Pennsylvania, Delaware, Northern Virginia, or Washington, D.C., contact us by email at [email protected], call us at 410-636-0730, or fax us at 410-789-3907, and don’t forget to keep in touch with us on Facebook!